E-mail:sales@bestchickencage.com

E-mail:sales@bestchickencage.com

YOU LOCATION:Home > Products > Battery Cage

Design, Types, Size, Structure, Advantages, Data, And Price

Our Nigerian Farm Case Of A Type Manual Layers Battery Cage System

3 Rows Of 4 Tiers Layer Battery Cage

What is battery cage?

Battery cage system is a kind of poultry cage, also named layer chicken cage, A Type manual layer battery cage is "A" frame shape.

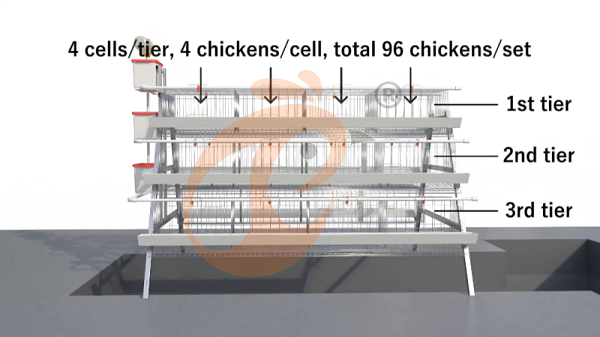

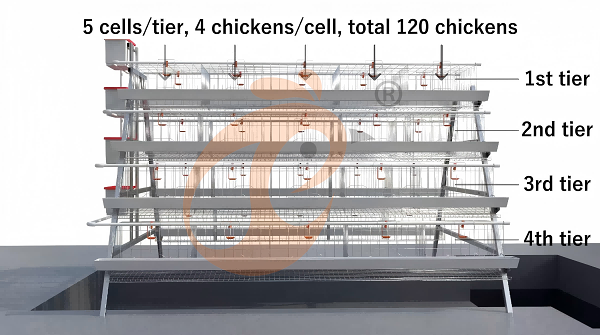

1. The popular types are 3 tiers, 96 layers per set, or 4 tiers, 120 layers per set.

2. Used for 1,000-30,000 egg laying hens farm in egg production industry.

3. Most poultry farmers choose feed mill, manure scrapers and manure dryer too.

Quick Details Of A Type Manual Layer Battery Cage System

3 tiers, 96 Chicken A Type Battery Cage Design

A shorter video to understand it very well

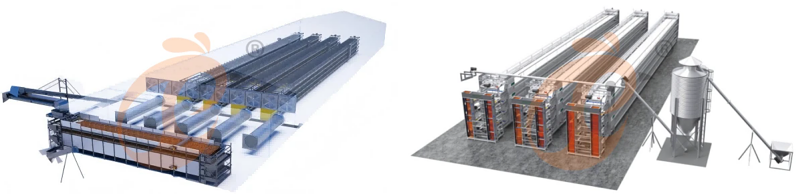

3D Showing

Sample Showing In Factory

| Item | Structural Description |

|---|---|

| Cage Type | A-type stepped multi-tier structure |

| Tier | 3 tiers, 4 tiers |

| Frame | Galvanized angle iron bar |

| Cage | Floor mesh, side mesh, rear mesh, front door |

| Egg Collection | Workers pick up |

| Feeding |

Workers add feed |

| Drinking | Automatic with water tanks and drinkers |

| Manure | Manure ditch below cages by scraper system |

| Installation | Modular assembly |

| Suitable Poultry House | Open or semi-closed poultry houses |

How To Choosing Battery Cage System?

Easy Tips To Choose Right Layer Battery Cage - A type battery cage VS H type battery cage

Learn introduction of A type automatic and H type automatic type, please check PRODUCTS

Comparison Item

A-Type Manual

A-Type Automatic

H-Type Automatic

Structural Type

A-type stepped structure

A-type stepped structure

H-type vertical stacked structure

Capacity Per Poultry House

1,000–30,000 birds

10,000–60,000 birds

50,000–300,000+ birds

Scalability

Limited

Moderate

Very high

Suitable Farm Type

Small or start-up farms

Medium-scale commercial farms

Large-scale industrial farms

Why Choose VANKE's A Type Manual Layer Battery Cages?

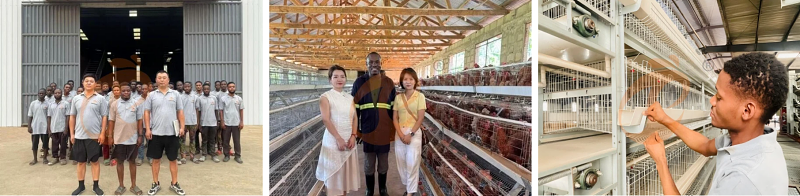

Nigeria-China Local Leading Battery Cage System Manufacturer and Supplier

Vanke Machinery And Equipment CO., LTD

We started in 2011, Our poultry battery cage and poultry farm equipment are selling in 90% Nigerian states.

1. Long lifespan - since our first cage arrived Lagos in 2011 till now, still working very well.

2. Fast delivery - Vanke has stock, paying in the morning, delivery in the afternoon or the second day.

3. Easy after service - Local team gave you quality replay no matter you are big or small farmers.

Layer Battery Cage Commercial Dimension

1. Hot sale type 1

- Tiers: 3 tiers

- Capacity/set: 96 chickens

- L X W X H: 2m by 1.8m by 1.5m

- House Size: 50 x 12 x 4.15-5.25 (L x W x H): 7,560 birds

- House Size: 100 x 12 x 4.15-5.25 (L x W x H): 15,480 birds

2. Hot sale type 2

- Tiers: 4 tiers

- Capacity/set: 160 chickens

- L X W X H: 2.2m by 2.4m by 1.75m

- House Size: 50 x 12 x 4.15-5.25 (L x W x H): 10,080 birds

- House Size: 100 x 12 x 4.15-5.25 (L x W x H): 20,640 birds

Layer Battery Cage Layout In Poultry House

A 20-second short video to help you learn it faster

Layer Battery Cage Price

The price depends on:

1. Cage material thickness and galvanization standard

2. Poultry house size and layout

3. Optional control systems

Reference Price Range:

USD 2.0–3.0 per bird, depending on configuration

Layer Battery Cage Structure

To learn it more imaginativeness, Combining with the the video of our local practical application in farm project in Nigeria

1. Layer Transfer Into Cages

- Workers move 12–16-week-old pullets into the layer cages.

- Standard stocking density places 3–4 birds per cage section, ensuring proper space and even distribution.

2. Drinking Through Nipple System

3. Feeding Routine

4. Egg Rolling & Collection

5. Manure Management

A 20-second short video showing how 3 scrapers working

- Manure falls directly into the manure pit without contacting hens or eggs.

Specific configurations are subject to customer requirements or final quotation.

If you are interested in other equipment of AI smart management, layers, broilers, pullets, feed, eggs, manure and so on, please directly click PRODUCTS

| Type | Tier/Set | Size(L x W x H)/Unit(M) | Cell Size(L x W x H) (CM) | Cells/Unit Per Set | Birds/Cells | Birds/Set | Space/Bird(CM2) |

| A1 | 3 | 2.2 x 2.4 x 1.65 | 43 x 38 x 38 | 30 | 4 | 120 | 418 |

| A2 | 4 | 2.2 x 2.4 x 1.95 | 43 x 38 x 38 | 40 | 4 | 160 | 418 |

| A3 | 5 | 2.2 x 2.6 x 2.6 | 43 x 38 x 38 | 50 | 4 | 200 | 418 |

For reference only, the exact size is based on the actual needs of the poultry farm and customer requirements, or our exact quotation.

1. Since its establishment in 2011, we have rich experience in localization services.

Nigerian local team

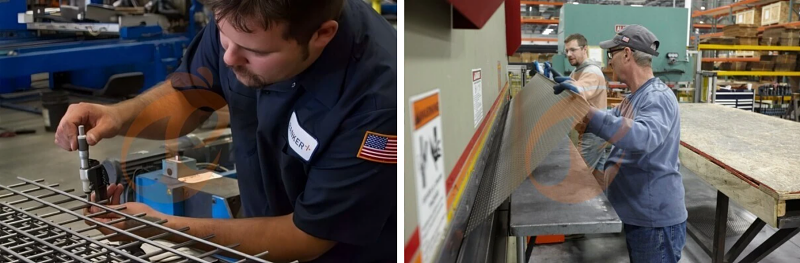

2. Constant communication with the United States and Europe, make high-quality battery cage and equipment.

Engineer inspection

3. Lagos local production, save customers 10% to 30% of costs.

Nigerian Factory, workshop and materials

4. Constantly innovate technologies, tailor intelligent project solutions for you.

Intelligent solution

5. Constantly expanding the team, the headquarters in Hong Kong and branches in Nigeria, Tanzania and Ethiopia are joint management.

Branches of China, Nigeria, Tanzania and Ethiopia

Vanke Machinery & Equipment Nig Ltd have serviced farmers and distributors since 2010.

Gain the high trust and recognition from customers to now.

Following farmers are some of our clients, welcome you!

Contact: Whatsapp 24 hours online +234 8111199996.

ADD: after Sinoma Office, 200 meters near Danco Filling Station, Lagos/Ibadan Expressway, Lagos State, Nigeria.

A Type manual layer battery cage system always compare with deep litter system when some farmers want to improve his common poultry equipment to advanced battery cages.

Here is the exact advantage of battery cage system vs deep litter system:

|

Comparison Metric |

Battery Cage System |

Deep Litter System |

|

1. Space Utilization & Stocking Density |

||

|

Space Data |

Approx. 430–550 cm² (0.45–0.67 sq. ft.) per bird, utilizing vertical space |

Recommended approx. 0.37–0.46 m² (4–5 sq. ft.) per bird, utilizing only floor space |

|

2. Production Performance |

||

|

Laying Rate (Daily) |

Approx. 88.8% daily egg production rate |

Approx. 85.9% daily egg production rate |

|

Egg Cleanliness Rate |

About 77% of eggs remain clean and marketable |

Only about 14% of eggs remain clean (mostly floor eggs) |

|

3. Feed Consumption & Conversion |

||

|

Average Weekly Feed Intake |

Approx. 707.6 grams/bird |

Approx. 740.6 grams/bird (higher due to increased activity) |

|

Feed Conversion Ratio (FCR) |

FCR is generally superior, with minimal feed wastage |

FCR is slightly lower; birds use more energy for movement |

|

4. Health & Mortality |

||

|

Mortality Rate |

Generally lower, easier disease management |

Generally higher, faster disease spread within the flock |

|

5. Economics & Return On Investment (ROI) |

||

|

Initial Investment |

Higher initial cost for equipment and automation |

Lower initial cost, suitable for small-scale farmers |

|

Return on Investment (ROI) |

Approx. 17.49% |

Approx. 13.93% |

|

Net Profit Per Bird (Annual) |

Significantly higher than deep litter system (up to 4.5 times more in some studies) |

Lower net profit margin |

1. All fittings are packed by wooden pallets and boxes, plastic wraps and boxes, nude packing, it depends.

2. Local factory and warehouse from branches of Ethiopia, Tanzania and Nigeria, depends on your order.

3. Full or less container from China branch by sea, depends on your order.

Nigerian factory, warehouse and delivery

Container shipping from China to Nigeria

Engineer installation In Nigeria

5 Essential Maintenance Tips For The A Type Layer Battery Cage System

1. Daily Inspection And Cleaning Of The Automatic Watering System

The cleanliness of the watering system is crucial for disease prevention.

2. Regular Manure Removal And Maintaining Proper Ventilation/Humidity

Hygiene management directly impacts flock health and the prevention of equipment corrosion.

3. Inspect The Structural Integrity Of Cage Frames And Metal Components

The structural integrity of the equipment guarantees safety and durability.

4. Maintenance And Testing Of Automated (Or Semi-Automated) Equipment

Ensure all mechanical components operate efficiently to minimize downtime and failures.

5. Strict Disinfection Procedures And Thorough House Cleaning

Prevention is better than cure; thorough disinfection breaks disease transmission chains.

SEND YOUR MESSAGE TO US

(* We will reply your inquiry to this Email as soon as we see it.)RECENT BOLGS

Comments

CONTACT US